Working Principle of an Electronic Balance

admin 2025-12-18 17:24:35

In the world of scientific and industrial measurements, accuracy and reliability are paramount. The electronic balance has emerged as a powerful tool for precision weighing, revolutionizing industries ranging from pharmaceuticals to manufacturing. Understanding the working principle of electronic balances is crucial for both new users and professionals who rely on these devices for exact measurements.

What is an Electronic Balance?

An electronic balance is an advanced weighing instrument that uses electronic sensors and digital signal processing to measure the mass of an object. Unlike traditional mechanical balances, which rely on a system of levers and counterweights, electronic balances offer faster, more accurate readings with a digital display. These balances are widely used in laboratories, educational settings, and industrial environments where precision is critical.

The Core Working Principle

The core of an electronic balance's functionality lies in its force sensor (usually a strain gauge) that detects small changes in weight and converts them into a readable digital signal. Here’s how it works:

1.Load Application:

When an object is placed on the balance’s weighing platform, the weight of the object generates a force that acts on the sensor.

2.Force Detection:

The sensor, typically made of a strain gauge or capacitive device, detects the force applied. In the case of a strain gauge, the material inside the sensor deforms slightly under the weight, changing its electrical resistance.

3.Signal Conversion:

The change in resistance or capacitance is measured and converted into an electrical signal. This signal is then amplified to ensure it is strong enough to be accurately processed.

4.Signal Processing:

The amplified signal is sent to the microprocessor within the balance, which uses complex algorithms to convert the electrical signal into a readable mass value.

5.Display:

Finally, the mass is displayed on a digital screen, providing the user with an accurate, real-time measurement of the object’s mass.

Key Components: The "Four Core Parts" of Precision Measurement

The accuracy of an electronic balance depends on the coordinated operation of four core components:

1.Sensor Module: Mostly adopts strain gauge or capacitive sensors. Strain gauges convert mechanical deformation into resistance changes (sensitivity up to 0.001Ω level), while capacitive sensors capture deformation through changes in plate spacing. Both types can achieve micro-change perception;

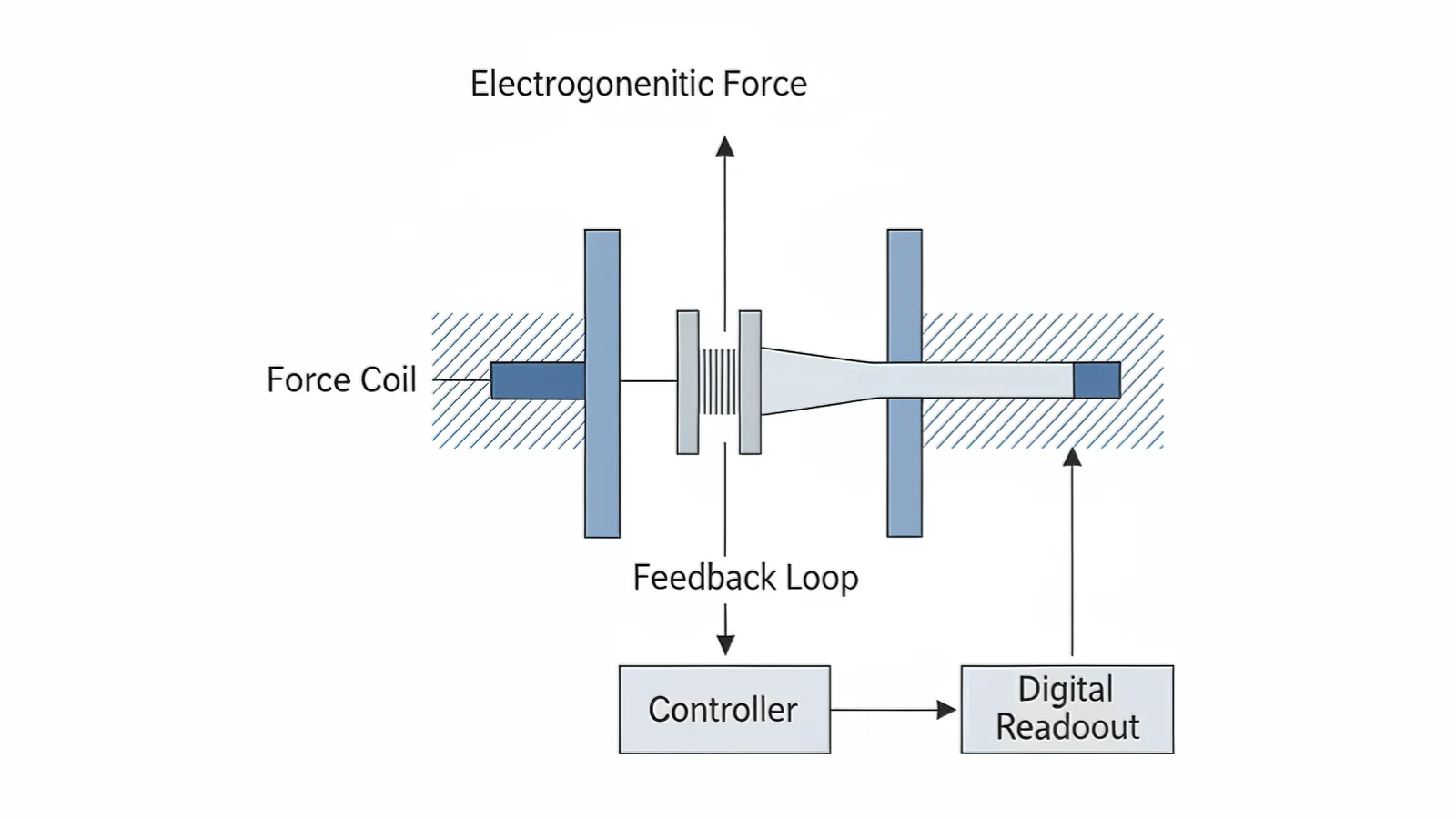

2.Electromagnetic Drive System: Consists of a permanent magnet and a moving coil. The permanent magnet provides a constant magnetic field, and the moving coil generates controllable electromagnetic force when energized. The response speed must reach the millisecond level to ensure rapid balance;

3.Signal Processing Unit: The core consists of an Analog-to-Digital Converter (ADC) and a microprocessor. The conversion accuracy of the ADC directly determines the lower measurement limit (high-end models have an ADC resolution of 24 bits, capable of capturing nanoampere-level current changes), while the microprocessor is responsible for algorithm calibration and error compensation;

4.Environmental Compensation Module: Built-in temperature, humidity, and air pressure sensors to real-time correct the impact of environmental factors on measurements (e.g., temperature changes cause fluctuations in coil resistance, which the system automatically compensates for).

Why Choose an Electronic Balance?

1. High Accuracy and Precision: Electronic balances offer remarkable accuracy, often with precision to the milligram or even microgram level, depending on the model. This makes them ideal for environments where exact measurements are critical, such as in pharmaceuticals, chemistry, and food processing.

2. Quick Readings: Compared to traditional mechanical balances, electronic balances provide almost instantaneous results, improving workflow efficiency in high-demand settings.

3. Built-in Calibration: Many modern electronic balances come with automatic calibrationfeatures, ensuring consistent results over time, even in fluctuating environmental conditions such as changes in temperature or humidity.

4. Digital Output: With the ability to connect to external devices like computers or printers, electronic balances facilitate easy data management and traceability, which is a vital feature for research and quality control procedures.

Applications of Electronic Balances

• Laboratories: Used in research to measure chemicals and substances with high precision.

• Pharmaceutical Industry: Ensures that medicines and compounds are weighed accurately during production.

• Manufacturing: Used for quality control in various products, ensuring consistent weight specifications.

• Educational Institutions: Provides students with hands-on experience in accurate measurement techniques.

The electronic balance has become an indispensable tool in both scientific and industrial fields. By leveraging advanced sensor technology, these balances offer fast, accurate, and reliable measurements, making them essential for industries requiring precision. Whether you're working in a laboratory, factory, or classroom, understanding the working principle behind these devices ensures you can use them to their full potential.

For more information about electronic balances and how they can benefit your operations, visit our website or contact our support team for expert advice!