Design Requirements and Sensor Requirements for Electronic Balances

admin 2025-12-31 18:45:15

As high-precision measuring equipment, the design of electronic balances must balance accuracy, stability, and ease of use. The performance of the core component, the sensor, directly determines the measurement grade of the balance. The following are detailed requirement standards for industrial/laboratory-grade electronic balances.

I、 Design Requirements for Electronic Balances

The core of electronic balance design lies in how to balance precision, stability, and reliability.

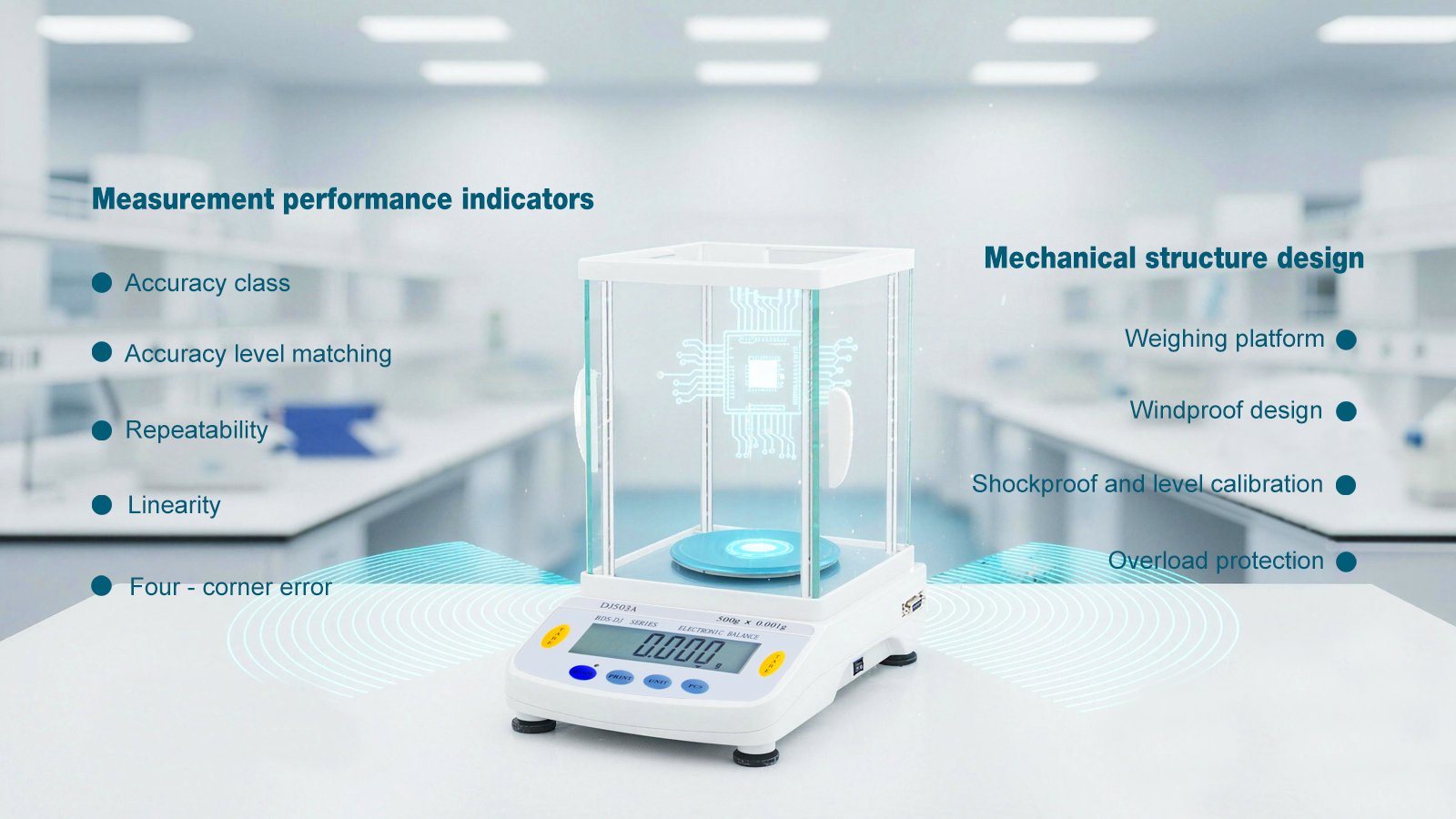

1. Metrological Performance Indicators

- Accuracy Class:According to the verification scale interval (e) and the actual scale interval (d), electronic balances are generally classified into Special Accuracy Class (Class I), such as semi-micro or analytical balances, High Accuracy Class (Class II), and Medium Accuracy Class (Class III).

Accuracy Grade Matching: Accuracy is classified according to usage. Laboratory analytical balances need to reach an accuracy of 0.0001g/0.001g, and industrial/commercial balances need to meet an accuracy of 0.01g/0.1g; the range must cover the target weighing range, and a 10%-20% overload margin should be reserved to prevent damage from overloading.

Repeatability:The consistency of results when the same load is weighed multiple times under the same conditions.

Linearity:The degree to which the displayed value is proportional to the actual mass across the weighing range.

Corner Load Error (Eccentric Load Error): When an object is placed at different corner on the weighing pan, the variation in the displayed value must remain within the maximum permissible error (MPE).

2. Structure and Material Design

Weighing Platform: Made of 304 stainless steel/aerospace aluminum alloy, with a smooth and corrosion-resistant surface. The flatness error of the platform is ≤0.1mm to avoid sample residue and weighing deviation.

Wind Shield (Essential for High-Precision Balances): A transparent tempered glass wind shield with liftable doors is designed to reduce the interference of air flow and static electricity on small weights; industrial balances can be simplified with dust-proof baffles.

Vibration Dampening and Leveling Calibration: The base must possess excellent damping performance and be equipped with a leveling bubble and adjustable feet to ensure that the gravity vector is perfectly perpendicular to the sensor's load axis.

Overload Protection: A mechanical limiting device must be integrated into the structure to prevent damage to the precision sensor components caused by excessive loads.

3. Electronic Circuitry and Software Requirements

Core Functions: Must integrate tare, calibration, and unit conversion (g/oz/ct, etc.) functions; high-precision balances need to add cumulative weighing, density measurement, and piece counting functions to meet diverse needs.

Temperature Compensation:The design must incorporate temperature compensation circuits or algorithms to counteract the effects of thermal expansion/contraction of materials and sensor temperature drift.

Automatic Zero Tracking - AZT:This ensures the display remains at zero under no-load conditions; however, a balance must be maintained between response speed and zero-point stability.

Multi-unit Conversion and Self-Calibration:Supports multiple weighing units; high-end products should feature internal motorized weights for fully automatic Internal Calibration.

Display and Operation: Equipped with an LCD/LED backlit display to support reading in low-light environments; the key layout is simple, supporting one-key calibration, and industrial models can be equipped with waterproof key design.

Data Output: Reserve RS232/USB/Bluetooth interfaces to support connection with computers and printers, realize data traceability, and adapt to the needs of industrial automated production lines.

Anti-Interference Ability: Equipped with electromagnetic shielding design to resist power grid fluctuations, static electricity, and radio frequency interference; the power supply supports AC 100-240V wide voltage, adapting to the power grid standards of different countries.

II、Sensor Requirements - Core Components

Is the "heart" of the balance. Different sensor technologies are selected based on the precision requirements of the balance:

1. Sensor Types and Suitability

- Electromagnetic Force Balance

Principle:Utilizes the electromagnetic force generated by a current in a magnetic field to balance the gravitational force of the object.

Accuracy Indicators:

The resolution must reach 0.0001g or higher, and the nonlinear error is ≤±0.05%FS (full scale).

The repeatability error is ≤±0.03%FS to ensure consistent measurement results.

Performance Stability:

Zero drift is ≤0.0001g/hour to avoid zero offset after long-term use.

The temperature coefficient is ≤0.0002g/℃ to reduce the impact of ambient temperature on measurement results.

Structural Requirements:

The iron core and coil are made of high-permeability stainless steel, and the coil is evenly wound to ensure linear output of electromagnetic force.

Equipped with an elastic support structure to reduce the impact of vibration on the sensor, with a response time of ≤1 second.

Applications:

Laboratory analytical balances and microbalances.

- Strain Gauge Load Cell

Principle: Utilizes the deformation of an elastic body under load, which changes the resistance of the mounted strain gauges.

Requirements: Low creep and low hysteresis. The elastic body material must possess excellent stability of the elastic modulus.

Applications: General electronic scales and industrial balances (typically with readability of 0.01g or lower

Core Performance Indicators

| Indicator | Requirements Description |

| Sensitivity | Response speed to minute changes in mass. |

| Temperature Drift | The deviation of sensor output caused by environmental temperature changes. |

| Creep | The change in sensor output over time under a constant rated load. |

| Insulation & EMC | Must feature robust electromagnetic shielding to prevent interference. |

III、Critical Matching in Design

Redundancy Design : The sensor capacity should exceed the balance's maximum capacity to avoid non-linear distortion.

Environmental Adaptability :Sensors must meet specific Ingress Protection (IP) ratings for humid or corrosive environments.

For more information about electronic balances or if you are looking to purchase an electronic balance, please contact our sales team or visit our website:www.bdscales.com